Miniature circuit breakers(MCBs) are one of the most widely used terminal protection devices in building electrical terminal distribution devices. Although miniature circuit breaker is a terminal electrical equipment, it is widely used in many applications such as construction engineering, civil lighting and so on because of its superior performance, convenient use and reasonable price. If the use of miniature circuit breakers with substandard quality, unnecessary losses may be caused. The following are the causes and possible consequences of substandard quality of some miniature circuit breakers.

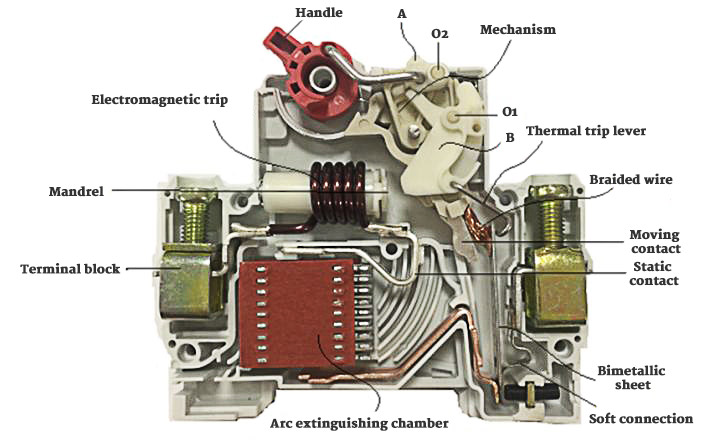

Structure of miniature circuit breaker

Unqualified tripping performance

Under the set environmental conditions, 1.13In current will not trip for 1h; under the set environmental conditions, 1.45In current will trip for 1h.

Main cause:

The quality of bimetal sheet used for overcurrent protection is unstable and the action time is discrete, which makes the manufacturer unable to inspect the product quantitatively.

Manufacturers usually use the 2.5In quick calibration method when calibrating miniature circuit breakers, but they have not verified the 1.13In and 1.45In action times corresponding to the 2.5In action time, which may cause the checked product action time to be inaccurate.

Insufficient accuracy of manufacturer's inspection equipment and instruments, inadequate proficiency of calibration technicians, and unsatisfactory standard test benches and constant greenhouses used by some manufacturers for factory inspection are all factors that cause inaccurate action time of products calibrated.

Possible consequences:

Miniature circuit breakers with over-current protection function trip abnormally without overload, which affects the normal power consumption of users and causes undue losses.

When an overload situation occurs, the miniature circuit breaker does not trip normally and does not play an overload protection function. Therefore, it cannot eliminate the fire hazard caused by the fault in actual use and prevent the danger from occurring.

Short-circuit capability of operation is not up to standard

Short-circuit capability is one of the main indexes of miniature circuit breakers, which is the characterization of miniature circuit breakers'capability and process design level.

1. Miniature circuit breaker housing break

Main cause:

The product enclosure material does not meet the performance requirements, the thickness of the enclosure is not enough or the proportion of the enclosure material is not correct, which makes the enclosure unable to withstand the arc energy produced by the circuit breaker when the short circuit current is interrupted, causing the circuit breaker housing to break.

Rivet material used for riveting does not meet the performance requirements, rivet material is too thin or riveting strength is not enough, which makes the product unable to withstand the arc energy produced by the circuit breaker when the short circuit current is interrupted, causing the circuit breaker housing to break.

The arc extinguishing performance is poor, the number of grid pieces used for arc extinguishing is not enough or the iron sheet is too thin. The riveting process of arc extinguishing grid is poor, and the red bar cardboard used for fixing is relatively thin, which causes the arc extinguishing grid to fall apart under the impact of arc energy, and the arc extinguishing iron sheet blocks the arc nozzle, so that the arc energy can not be released from the nozzle, causing the circuit breaker shell to crack.

2. The phenomenon that miniature circuit breakers can not close

Main cause:

The quality of bimetal sheet used for overcurrent protection is unstable. Under the impact of large capacity short circuit current, it causes serious variant, which makes the tripper unable to recover.

Contact material does not meet the requirements, some enterprises use non silver based alloy or bare copper, which causes excessive burning of the contact when breaking short-circuit current.

The inner soft connection of product and the small wire diameter of coil result in high temperature when large capacity short circuit current passes through, which leads to the variation of internal mechanism and the inability of closing mechanism.

The arc extinguishing performance is poor and it is impossible to extinguish the arc quickly, so that the arc energy generated during the breaking process stays inside the product, resulting in the burning of the internal mechanism.

3. The phenomenon that miniature circuit breakers are not energized

Main cause:

The product contact material does not meet the requirements or the action time is too slow during the breaking process, which causes the contact to be seriously burned. Although the product handle is in the closing position, the dynamic and static contacts cannot be contacted.

The inner soft connection wire diameter is too small or the welding process of the soft connection does not meet the process requirements. Under the impact of large capacity short circuit current, the soft connection will burn out or the soft connection will be de-welded.

4. Miniature circuit breaker produces withstand voltage breakdown

Main cause:

The material of product shell does not meet the performance requirements and can not withstand the ablation of electric arc during the breaking process, resulting in serious carbonization in the product interior.

Due to high temperature caused by large capacity short circuit current and impact of arc energy, the position of internal device of the product changes or even distorts, thus the safety distance of the product itself can not meet the requirements.

5. Early tripping and non-tripping of miniature circuit breakers

Main cause:

The quality of bimetal sheet used for overcurrent protection is unstable. Under the impact of large capacity short circuit current, it causes excessive variant and makes the tripper unable to return to its original position.

The product is not qualified for trip characteristic verification at the factory.

Possible consequences:

When short circuit is caused by electric equipment or line fault, miniature circuit breaker must have reliable breaking capacity. If the short-circuit current of the product can not be cut off normally, the hidden danger of flood and fire caused by the fault in the actual use cannot be eliminated; in the larger power system, there are many protection switches. If the miniature circuit breaker fails to break in time when the short circuit occurs at the terminal, it will cause delay protection of the superior protection switch, resulting in a large-scale blackout and unnecessary losses.

Classification of Circuit Breakers

The function of circuit breaker is: under normal circumstances, the motor is started and stopped by making infrequent closing and breaking circuits; when overload, short circuit or undervoltage (undervoltage) occurs in the circuit or motor, the circuit can be automatically cut off to protect it. According to the different protection objects, circuit breakers can be divided into four types: distribution protection type, motor protection type, household and similar household protection type and residual current protection type.

Distribution protective circuit breakers to protect power supply and electrical lines (wires, cables) and equipment.

Motor protection circuit breaker is designed for infrequent motor starting, breaking during operation, and protection in case of overload, short circuit and under voltage of motor.

Protective circuit breakers for household and similar household use to protect lighting lines, household appliances, etc.

Residual current protective circuit breakers(leakage protective circuit breakers), are protective devices used to protect people from electric shock hazards and electrical fires.