Miniature circuit breaker(MCB) is a small-capacity plastic case circuit breaker with very compact structure. It is a branch of low-voltage circuit breakers, and has now become a major category of terminal electrical appliances. Miniature circuit breakers are protective electrical appliances and are mainly used to protect the safety of electrical circuits and equipment. When electrical circuits or electrical equipment are overloaded, short-circuited and other faults, their tripping devices should be able to act in a timely manner to reliably cut off the circuit; when When the electrical circuit or electrical equipment is in a normal state, its main contact should be able to reliably connect to the circuit, and its trip unit should not malfunction. The main failure modes of miniature circuit breakers can be divided into operation failures, misoperation failures and refusal operation failures. (How to choose miniature circuit breaker?)

Nader Miniature circuit breakers(MCB)

Structure of miniature circuit breaker

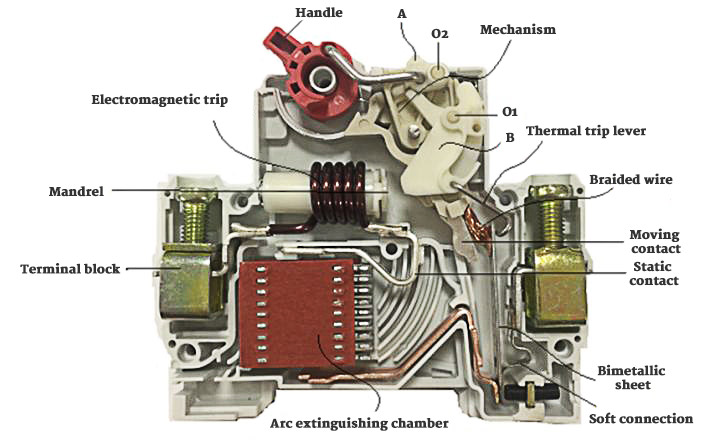

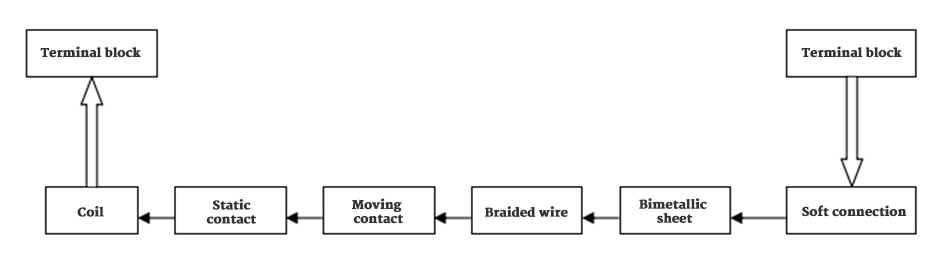

Miniature circuit breakers are generally composed of operating mechanisms, contacts, protection devices (various releases), arc extinguishing systems, etc.

Structure of miniature circuit breaker

Contacts

The function of the moving and static contacts is to perform the making or breaking action before and after the circuit fails, and the technical requirement of the contact of the miniature circuit breaker is to have the ability to make and break the limit short-circuit current and the circuit current below stably and reliably. At the same time, it needs a current that can achieve long-term work, and there will be no serious wear and tear after the action is executed within the specified number of service life.

Arc extinguishing system

The arc extinguishing system is used to extinguish the arc produced when the contacts are disconnected from each other. The arc extinguishing system consists of two parts: one is a strong spring mechanism, which enables the contacts of low voltage circuit breakers to be quickly separated; the other is an arc extinguishing chamber located above the contacts. When the main contact is disconnected, the grille in the arc extinguishing chamber senses a strong magnetism. The arc is drawn into the grid and burned off in stages to protect the contacts from damage.

Protective device

In miniature circuit breakers, trippers are usually used to protect the distribution system, including different forms of trippers such as undervoltage, excitation and overcurrent. Undervoltage protection uses undervoltage trippers in the structure of miniature circuit breakers to monitor the fluctuation amplitude of operating voltage. When voltage drops to 70% to 35% of rated voltage or a fault occurs, it feeds back to the circuit breaker and immediately performs a breaking action, which prevents the circuit breaker from closing if the voltage falls below 35%.

Operating mechanism

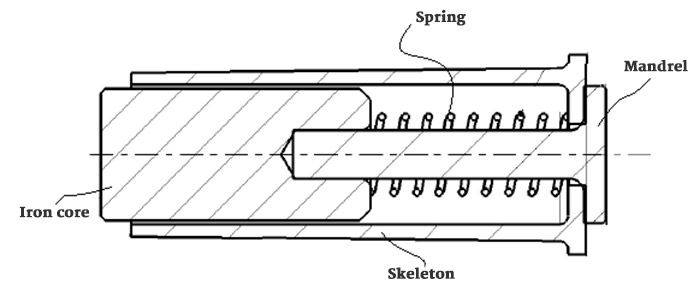

The operation mechanism of the miniature circuit breaker consists of magnetic trip and thermal trip. The magnetic trip device consists essentially of a composite magnetic system with a spring-loaded buffer with a magnetic spring plug in the silicon fluid and a normal magnetic trip. The thermal tripping device is surrounded by a bimetal strip and the heater coils are wound around to generate heat based on the current flow.

The working principle of miniature circuit breaker

The principle of miniature circuit breaker overload protection

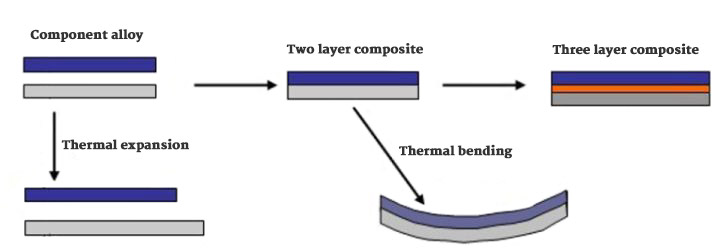

The overload protection function of miniature circuit breakers is based on the principle that bimetals bend regularly with increasing temperature. When the miniature circuit breaker is in normal operation after closing, because the inner bimetal sheets are heated by a certain current, the two metals are bent due to different coefficient of thermal expansion. When the normal current passes, the bending angle of the bimetal sheets is not large, so the thrust is not enough to trip the tripping mechanism. When the line is under general overload, the bending angle of the bimetal sheets is large and the tripping mechanism is touched. A lever with sufficient thrust to push the tripping mechanism enables the miniature circuit breaker to trip for overload protection. Bimetal sheets are bent differently by the amount of current flowing through them. When a circuit is generally overloaded, the trip time of the circuit breaker is usually longer due to the low overload current.

Thermal bimetals are composite functional materials consisting of two or more metals or alloys with different expansion coefficients that are firmly combined along the entire contact surface and have a shape change with temperature. In the component alloys of hot bimetal, the one-layer alloy with higher coefficient of expansion is generally called active layer, while the one with lower coefficient of expansion is called passive layer. When current flows through the bi-gold, it heats up. Because the expansion coefficients of the active and passive layers are different, the two layers will bend to one side under the same heat. In addition, to meet the functional requirements, a series of resistive thermal bimetals with different resistivity can be obtained by adding different thickness intermediate layers between the active layer and the passive layer as the diversion layer.

Principle of short circuit protection of miniature circuit breaker

The short circuit protection function of the small circuit breaker is achieved by the instantaneous tripper. Instantaneous trippers are connected in series to the circuit and have few coil turns (typically less than 10 turns).According to the analysis of F=IN (suction is proportional to the product of current and turns), when the circuit is in normal operation, the suction generated by normal working current is not enough to overcome the spring reaction force because of the small turns, so the circuit can work normally. When the line is short-circuited or severely overloaded, a high current flows through the induction coil and generates a strong magnetic field. Since the generated current is several times or more different than the current in normal operation, the turns of the coil remain unchanged, but the current increases several times or tens of times, so the suction increases several times or tens of times. Pushing the lever causes the circuit breaker to trip quickly because of the electric current. The current is very high and the trip time of circuit breaker is usually within 0.1s. In addition, as long as the reaction spring is selected reasonably, the setting requirements of instantaneous trippers of type B, C and D can be met.

Classification of miniature circuit breakers

Type B

This type of miniature circuit breaker will trip instantaneously three to five times its rated current. These are commonly used for resistive or small inductive loads where switching surges are very small. Therefore, these apply to residential or light commercial facilities.

Type C

This type of miniature circuit breaker will trip instantaneously at a rate five to ten times its rated current. These are commonly used for highly inductive loads where switching surges are high, such as small motors and fluorescent lighting. Therefore, type C miniature circuit breaker is more suitable for handling high short circuit current values and is suitable for highly sensitive commercial and industrial installations.

Type D

This type of miniature circuit breaker will trip instantaneously at 10 to 25 times its rated current. These are usually used for very high inductive loads where high surge currents occur very frequently. Suitable for specific industrial and commercial applications, including X-ray machines, UPS systems, industrial welding equipment, large winding motors, etc.