In order to use the relay correctly, while selecting the relay and understanding its characteristics, it is also necessary to understand some precautions in use to ensure the reliable operation of the relay.

The relay has the following precautions in use:

1. The use of the relay should meet the various parameter ranges listed in the product manual as far as possible.

2. The rated load and life are a reference value and will vary greatly according to different environmental factors, load properties and types, so it is best to confirm in actual or simulated actual use.

3. Try to use rectangular wave control for DC relays, and use sine wave control for AC relays.

4. In order to maintain the performance of the relay, please be careful not to drop the relay or subject it to strong impact. It is recommended not to use the relays that have fallen.

5. The relay should be used as much as possible in an environment with normal temperature and humidity, with little dust and harmful gases. Harmful gases include gases containing sulfur, silicon, and nitrogen oxides.

6. For the magnetic latching relay, it should be placed in the action or reset position as required before use. Pay attention to the polarity and pulse width when applying voltage to the coil.

7. For polarized relays, please pay attention to the polarity (+, -) of the coil voltage.

Contact

The contact is the most important structural part of the relay. The service life of the contact is affected by the contact material, the voltage and current value on the contact (especially the voltage and current waveforms at the time of on and off), load type, and switching Affected by frequency, environmental conditions, contact form, contact bounce phenomenon, etc., contact failure is generally caused by material transfer, adhesion, abnormal consumption, and increase of contact resistance.

Load

Generally, the size of the resistive load is recorded in the product manual, but these alone are not enough. It should be tested and confirmed in the actual contact circuit. The minimum load recorded in the product manual is not the standard lower limit that the relay can reliably switch. The reliability of this value is different according to the on-off frequency, environmental conditions, changes in the required contact resistance, and absolute value.

Voltage

When the inductive circuit is disconnected, the contact circuit has a reverse voltage greater than the circuit voltage. The higher the voltage, the greater the energy, which leads to the increase in contact consumption and material transfer. Therefore, it is necessary to pay attention to type and size of the load controlled by the relay contact.

Under the same current, the direct current (DC) voltage value that the relay can reliably switch is much lower than the alternating current (AC) voltage value. Because the alternating current has a zero point (the point at which the current is zero), the generated arc is easily extinguished, and the DC , The generated arc can only be extinguished after the gap between the contacts reaches a certain value, making the arc last longer than the AC situation, and aggravating the consumption of contacts and material transfer.

Current

When the contact is closed and opened, the impact current has a great influence on the contact. For example, when the load is a motor or an indicator light, the greater the inrush current when closing, the more the contact is consumed and the material transfers, and it is more likely to cause the contact to stick and fail to open. Please confirm it during actual use.

Need to pay attention in use

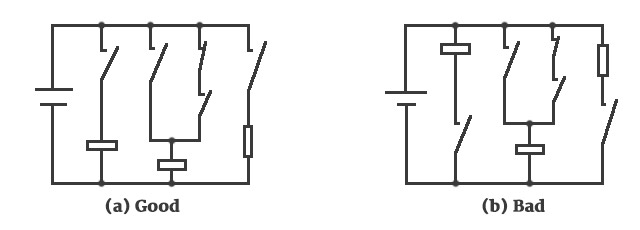

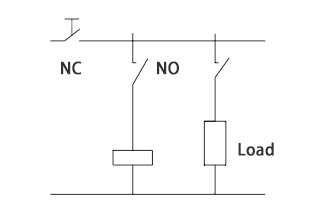

1. Avoid a relay that makes and breaks both large loads and small loads. Because it is easy to produce contact spatters when switching on or off a large load, they will attach to the contacts of the small load on and off, leading to contact failure. If you have to use it in this way, please place the contacts that make and break the small load above the contacts that make and break the larger load during installation, but the reliability of the relay will be affected.

2. When the two sets of contacts are connected in parallel, the reliability of the connection can be improved, but the load capacity cannot be improved, because the two sets of contacts cannot be opened or closed at the same time.

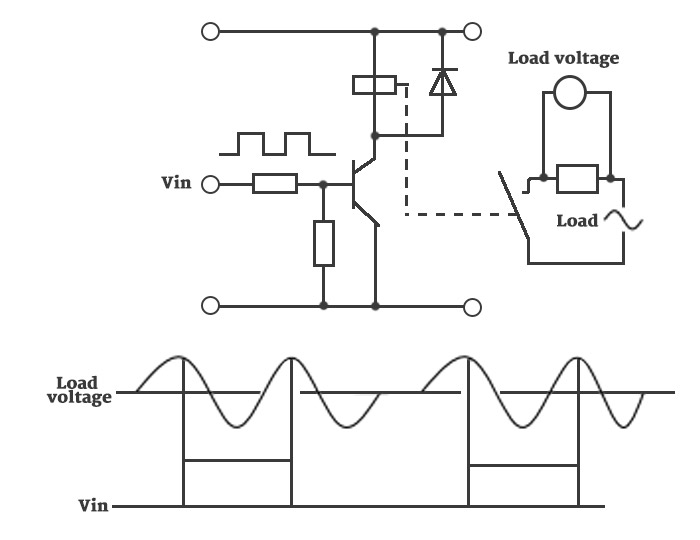

3. Regarding the synchronization of the contact action and the AC load phase: When the relay contact action is synchronized with the alternating current phase of the switched load, if the contact is always turned on or off when the load voltage is high, it will cause the contact bonding or material transfer, which will lead to premature failure of the relay. When the relay is driven by a timer, a microcomputer, etc., the power phase synchronization phenomenon occurs.

4. When the relay is used at high temperature, its electrical durability will be lower than that at normal temperature, so please confirm it in actual use.

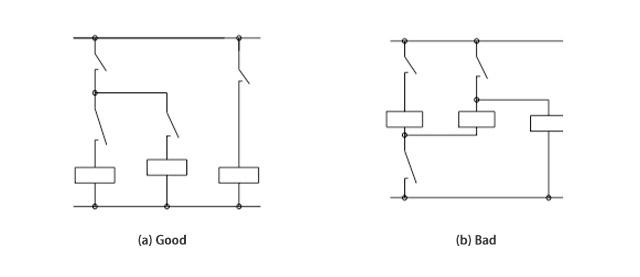

5. When there are multiple sets of contacts, please arrange the contacts on the same pole of the power supply as much as possible, and the load on the other pole of the power supply, so as to prevent the possibility of a short circuit due to the voltage difference between the contacts and the contacts.

6. Avoid short circuits between contact groups. Due to the miniaturization of electrical control equipment, the control components tend to be miniaturized. Therefore, when using relays with multiple sets of contacts, please pay attention to the type of load and the voltage difference of each set of contacts. Each set of contacts is recommended. It is best not to have an excessive voltage difference between them to avoid short circuits between contact groups.

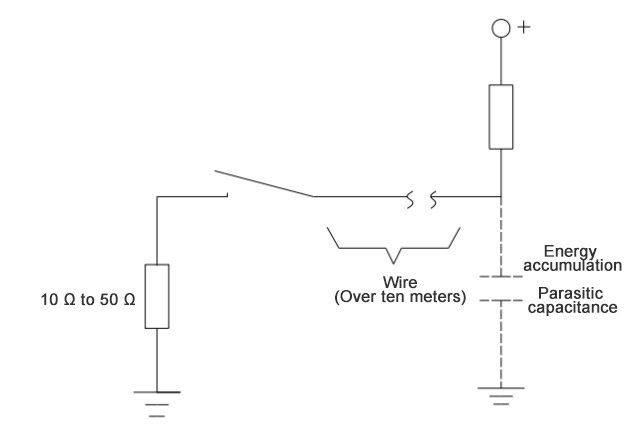

7. In the relay contact circuit, when using a long wire longer than tens of meters, due to the presence of parasitic capacitance in the wire, an impulse current will be generated. Please connect a series resistance (about 10Ω~50Ω) to the contact circuit.

8. Precautions for electromagnetic relay contacts: When leaving the factory, the electromagnetic relays are all set to the reset state, but during transportation or when the relay is installed, it may become the action off state due to impacts, etc., so during construction use (power access Time) Set it to the necessary off state as required.

Contact protection

1. When the motor, capacitor, solenoid or lamp load is connected, it will cause an impulse current several times the steady-state current.

When inductive loads such as solenoids, motors, and contactors are disconnected, reverse voltages of hundreds to thousands of volts will be caused. Generally, the critical insulation breakdown voltage of air at normal temperature and pressure is 200~300V, so if the reverse voltage exceeds this value, a discharge will occur between the contacts.

Both impulse current and reverse voltage will greatly damage the contacts and significantly shorten the service life of the relay. Therefore, proper use of the contact protection circuit can increase the service life of the relay.

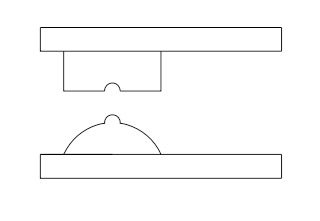

2. The material transfer phenomenon of the contact refers to the transfer of one contact material to the other contact. When the material transfer is severe, the unevenness of the contact surface is visible to the naked eye.

Generally, the material transfer of the contact is caused by the unidirectional flow of a large current or the inrush current of a capacitive load, which mostly occurs in a DC circuit, and generally exhibits a convex-concave shape. Therefore, the proper use of contact protection circuits or the use of AgSnO contacts with better resistance to material transfer can alleviate the material transfer phenomenon of the contacts. For large-capacity DC loads (a few A to tens of A), it must be tested and confirmed in actual applications.

3. Generally, inductive loads are more likely to cause damage to the contacts than resistive loads. If you use an appropriate protection circuit, the impact of the inductive load on the contacts can be basically equivalent to that of the resistive load, but please note that if it is used incorrectly, it may be It has the opposite effect.

4. When installing protective components such as diodes, C-Rs, and varistors, they must be installed next to the load or contacts. If the distance is too far, the protection effect will be unsatisfactory. It is recommended to install within 50CM.

Coil

Applying rated voltage to the coil is the basis for the normal operation of the relay. When only applying a voltage exceeding the operating voltage, the relay can work, but considering that changes caused by power supply voltage fluctuations and temperature rise will affect the normal operation of the relay, the rated voltage must be applied to the coil.

Type

AC action type (hereinafter referred to as AC type)

Generally, the working voltage of AC type relays is basically 50Hz (or 60Hz) power frequency voltage. It is recommended to choose products with standard voltage specifications listed in the product manual.

For AC type relays, due to eddy current loss, hysteresis loss and reduction of coil efficiency, the temperature rise is generally higher than that of DC type. When the voltage exceeds ±10% of the rated voltage, it is easy to produce a buzzing sound, so please pay attention to the fluctuation of the power supply voltage.

For AC type relays, when the coil is de-energized, there must be no residual DC component voltage in the power supply circuit, otherwise the relay may not be released normally. And the residual AC component voltage is as close as possible to 0VAC, otherwise it may cause the relay to produce a buzzing sound.

DC working type (hereinafter referred to as DC type)

Generally, DC relays are mostly voltage-driven. It is recommended to choose products with standard voltage specifications listed in the product manual.

Please confirm the voltage polarity of each relay coil in the manual. If a suppression diode or a display device is added, once the coil voltage is reversed, the relay will malfunction, or the additional components will operate abnormally, or even lead to a short circuit. Connecting a diode or a display device (light-emitting diode) to the coil in parallel will cause the relay to prolong its release time and may affect the electrical durability. Please be careful.

In addition, for polarized relays, if the polarity of the voltage applied to the coil is opposite to the specification, the relay will not work.

Coil input power

AC coil input power

In order to make the relay work stably, please apply the rated voltage to the coil. If a voltage that cannot fully operate the relay is applied (continuously applied) to the coil, the coil will heat up abnormally, causing abnormal loss of the coil.

The power supply voltage of AC type relay is best sine curve, because the AC coil can suppress the buzzing sound better in the case of sine waveform, if the waveform is distorted, this suppression function cannot be well exerted.

If devices such as motors, solenoids, transformers, etc. are connected to the drive circuit of the relay, when these devices work, the voltage on the relay coil will decrease, causing the contacts of the relay to vibrate.

If a load with large fluctuations such as a motor is used, please separate the drive circuit of the coil from the power circuit according to the application.

If the AC relay cannot work stably, the AC can be converted to DC, and then an appropriate DC relay can be selected.

DC coil input power

In order to work stably, it is recommended to use a coil rated voltage with a ripple change rate of less than ±5% for the voltage applied across the coil of the DC relay, otherwise the relay will work unstable, causing contact bonding or abnormal loss. This is especially true when devices such as motors, solenoids, and transformers are connected to the drive circuit of the relay.

As the power supply of DC type relays, there are batteries, full-wave or half-wave rectifier circuits with filter capacitors, etc. These different types of power sources will affect the operating characteristics of the relay, so please test and confirm in actual use.

Maximum allowable voltage of the coil

The maximum allowable voltage of the coil is not only limited by the temperature rise of the coil and the heat-resistant temperature of the coil enameled wire insulation material, but also by the thermal deformation and aging of the insulation material. In particular, it should not damage other machines, endanger human safety or cause fire, so it must be restricted within a certain range.

The maximum allowable voltage is the maximum value of the voltage that can be applied to the relay coil, not the value that allows continuous application.

Coil temperature rise

During the operation of the relay, the coil heats up and the temperature rises. Generally, when the on-time is less than 2 minutes under the pulse voltage, the temperature rise of the coil is related to the on (ON) time and the ratio of on and off (OFF), and various relays are basically the same.

The temperature rise of the coil will cause the increase of the coil resistance, and the operating voltage will increase accordingly. The temperature coefficient of resistance of the copper wire increases by about 0.4% per 1°C, and the coil resistance increases by this ratio.

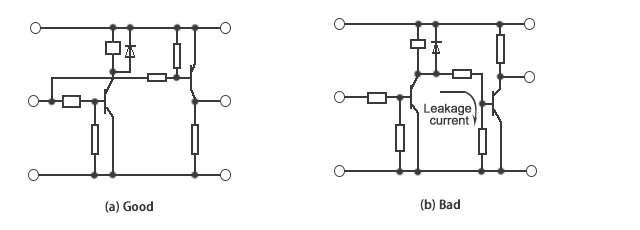

Leakage current

When designing the circuit, please pay attention to avoid leakage current flowing through the coil when the relay is not working.

Coil applied voltage and operating time

AC type electrical appliances will have a deviation in the operating time depending on the phase when voltage is applied to the coil. For DC type relays, even if the voltage applied to the coil is increased, the relay's operating time will be appropriately accelerated, but the rebound when the contacts are closed will also become larger. Working under rated load or high inrush current will lead to reduced life or contact bonding, so attention needs to be paid.

Precautions for magnetic latching relay coil

1. Coil voltage

Please confirm whether the direction of the voltage applied to the coil is correct, otherwise the relay may not operate.

Due to the characteristics of magnetic latching relays, it is not allowed to apply voltage to the coil for a long time to prevent the relay from overheating and burning.

2. Self-locking of the relay

Please avoid using the relay's own normally closed contact to cut off its own coil, as this will cause malfunctions due to the instability of the relay's action.

3. When using several relays in parallel

When the magnetic latching relay coil is connected in parallel with other relay coils or solenoids, please add a diode to prevent reverse voltage from affecting the normal operation of the relay.

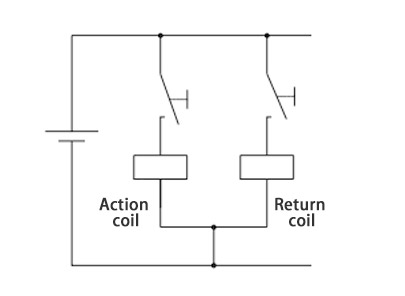

4. Precautions for dual-coil relays

Please do not apply voltage to the setting coil and reset coil at the same time, otherwise it will cause abnormal heating, abnormal operation or even abnormal loss of the relay.

When the circuit needs to connect either terminal of the action coil and the return line, and the other terminal is connected to the same pole of the power supply, please connect the two terminals to be connected directly (short-circuit) and then connect to the power supply. The insulation between the two coils can be kept good.

Other matters needing attention

1. When several relays form a series-parallel circuit, please pay attention to avoid malfunction due to bypass current and leakage current.

2. During the operation of general relays, there are stages such as contact pressure changes, contact jitter, and contact instability. When the voltage applied to the coil is gradually increased, the time of this unstable stage will become longer and affect The service life of the relay. In order to minimize the impact of this situation on the relay, please try to use a step voltage (using a switch circuit) to power the coil.

3. If the power cord is long, be sure to select the relay according to the principle of applying the rated voltage after measuring the voltage across the relay coil.

If the long-distance wiring is performed in parallel with the power line, when the coil power is disconnected, the two ends of the coil will generate voltage due to the parasitic capacitance of the wire, which will cause poor release. In this case, please connect bypass resistor both ends of the coil.

4. When the coil is continuously energized for a long time, the coil's own heating will promote the aging of the coil insulation material and the deterioration of its characteristics. Therefore, in this case, please use a magnetic latching relay. When a monostable relay must be used, please use a sealed relay that is not easily affected by the external environment, and adopt a proper protection circuit to prevent loss in case of poor contact or disconnection.

5. When the on-off frequency is less than once a month, please check the connection status of the contacts regularly. If the contacts are not on or off for a long time, an organic film may be formed on the surface of the contacts, causing poor contact.

6. When the relay is placed in a high temperature, high temperature environment or continuously energized, if the coil is grounded, it will easily cause the coil to be electrically corroded and cause disconnection, so please try not to ground the relay coil. If the coil has to be grounded, set the control switch at the coil end of the relay to the positive end of the coil.

Performance

1. Plastic-encapsulated relays have good environmental resistance, but please pay attention to the following matters when using them to avoid malfunctions.

Plastic-encapsulated relays are not suitable for environments with special air-tightness requirements. Please avoid using them at pressures other than 86kPa~106kPa. And avoid using in flammable and explosive gas environment. In this case, use a sealed relay.

When cleaning the printed board after soldering to the printed board, it is recommended to use an alcohol-based cleaning fluid for cleaning.

Please avoid ultrasonic cleaning. If ultrasonic cleaning is used, it may cause the coil disconnection and slight adhesion of the contacts.

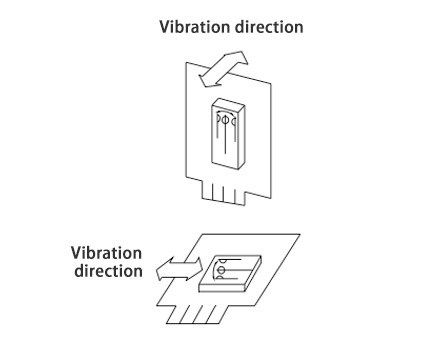

2. When the relay is subjected to a strong impact, the contacts will open instantly, which may cause malfunction. Therefore, when it is installed on the same board with other shock-producing devices (such as electromagnetic switches, air switches, etc.), countermeasures must be taken to reduce the impact of the shock on the relay, such as making the impact direction match the opening and closing direction of the relay's contacts and The movement direction of the armature is at right angles, or these devices are installed on different boards, or buffer sheets are used. In addition, when the relay is in a vibrating environment for a long time (such as voltage, etc.), please avoid using it in combination with a socket. It is recommended to solder the relay directly to the board.

3. When transporting a relay or a device equipped with a relay, if there is a large vibration or impact, it may cause malfunction of the relay. Please take a buffer package that can control the vibration and impact within the allowable range.

Surroundings

1. Please note that the ambient temperature of the place of use should not exceed the value specified in the product manual.

In addition, when there is a lot of dust in the surrounding environment, or sulfide gas (SO2, H2S, etc.) or organic gas, sulfide film, oxide film or dust will be formed on the contact surface, which will cause unstable contact and contact failure. Therefore, please choose a sealed relay. If you choose plastic-encapsulated relays, you need to test and confirm in actual use.

2. Please avoid using the relay in an environment containing the following gases. In these environments, plastic-encapsulated circuit breakers cannot avoid the influence of these gases on the contacts. Please use sealed relays.

Silicon environment: If there are silicon-based substances (such as silicone rubber, silicone oil, silicone-based paints, silicone fillers, etc.) around the relay, they will generate silicon-containing volatile gases, which may cause silicon to adhere to the contacts and cause poor contact.

Sulfide gas (SO2, H2S): Sulfide gas is easy to vulcanize the contacts, resulting in poor contact or non-conduction.

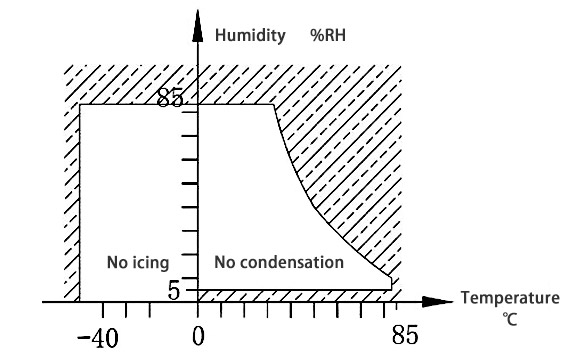

Nitrogen oxide gas (NOX): If the load that is prone to arcing is turned on and off in a high temperature environment, the NOx generated by the arc will react with the moisture absorbed from the outside to form nitric acid, thereby corroding the internal metal parts to the breaker Work brings obstacles. Do not use in an environment with a temperature higher than 85%RH (value at 20°C).

3. Please do not use or store the relay in an environment where the relay will be attached to water, chemicals, solvents, oil, etc., because water and chemicals will cause parts to rust and plastics will age. Thinner and oil will cause the label to disappear or the parts to age. For relays using PC enclosures, some organic solvents will cause the enclosure to swell and crack.

4. When using, storing and transporting, please avoid direct sunlight, and keep normal temperature, normal temperature and normal pressure. The temperature and temperature range that can be used, transported, and stored are shown in the non-shaded area in the figure below. The allowable temperature varies with the type of relay.

The recommended temperature and temperature range for use, transportation and storage are:

(1) Temperature: 0℃~40℃

(2) Humidity: 5%RH~85%RH

(3) Air pressure: 86kPa~106kPa

Shape and installation

1. Generally, the bottom view is obtained from the projection of the PCB terminal surface of the relay, and the top view is obtained from the opposite direction (ie, the top surface of the relay housing). Please pay attention when using the product manual and installing the relay.

2. Unless otherwise specified, the installation direction of the relay is generally any direction, but in order to make the relay work more stable and reliable, the installation direction also needs good consideration.

The ideal installation method is to make the movement direction of the contact and the movement direction of the armature at right angles to the vibration and impact direction. Especially when the coil is not energized, the vibration and impact resistance of the normally closed contact is weak, and its performance can be guaranteed if the installation direction is appropriate.

When installing, try to keep the contact surface of the relay in a vertical direction, so as not only to avoid the accumulation of garbage and dust.

3. When multiple relays are installed in close distance, the mutual interference of heat may cause abnormal heating. To avoid heat accumulation, please set a sufficient installation distance. When multiple substrates are stacked and installed, please be careful not to make the ambient temperature of the relay exceed the specified value in the product manual.

4. Please do not use the ultrasonic cleaning method to clean the relay, because the ultrasonic will cause contact bonding, coil disconnection and other faults.

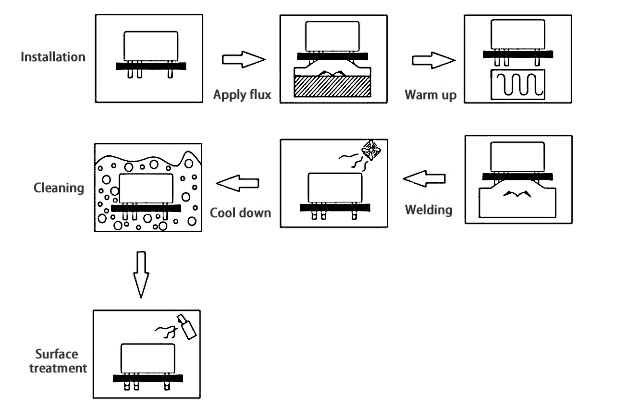

5. The installation and welding of THT relays are generally divided into the following steps.

Note that if flux enters the relay accidentally, the function of the relay will be impaired. Due to the different protective structures, there will be problems that are not suitable for automatic welding or automatic cleaning.

Other matters needing attention

Please note that when the relay is working normally, there is a danger of electric shock if you touch it with your hands.

Please note that please cut off the power before installing, maintaining and troubleshooting the relay (including terminal blocks, sockets and other connecting parts).

Please note that when making terminal connections, please refer to the connection diagram in the product manual first, and then connect correctly. If the connection is wrong, it may cause unexpected malfunction, abnormal heating, fire, etc.

In the event of contact bonding, poor contact, disconnection, etc., it may endanger other property or even life, please use double safety devices.