We usually encounter the concept of "safety level" in the design of electrical control circuits. So how to distinguish the safety level of electrical control circuits? How to design the circuit to meet the requirements of safety certification?

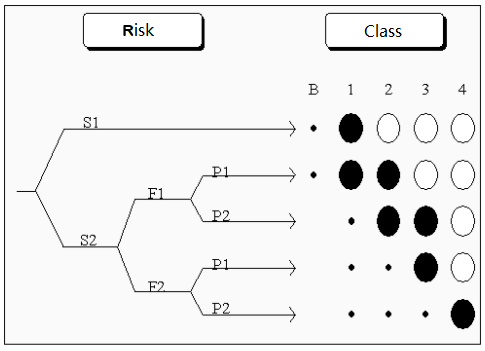

First, before designing a set of machines, a risk assessment of the machine must be carried out. From all aspects and parts, evaluate what kind of danger this machine will bring, and finally determine the danger level of this machine (or a part of it). According to the European machine safety standard EN954-1, the hazard levels are divided into five levels: B, 1, 2, 3, and 4, with the hazard levels increasing sequentially, and level 4 is the highest hazard level. The classification and determination of hazard levels are shown in Figure 1:

S - Degree of injury; 1 = minor injuries; 2 = serious injury or death; F - Time and degree of danger; 1 = from nothing to often; 2 = from frequent to persistent; P - Possibility of avoiding danger; 1 = may be under certain conditions; 2 = impossible.

After completing the risk assessment of a machine (or a part of it) and determining its hazard level, a series of measures must be taken to reduce the risk. Such as the design improvement of the mechanical structure, the increase of safety protection measures, the use of safety control circuits and so on. The design of the safety control circuit must also meet the required safety level. According to the European machine safety standard EN954-1, corresponding to 5 levels of hazard levels, the safety level of the control circuit is also divided into B, 1, 2, 3, 4, a total of five levels, the safety level is increased sequentially, and level 4 is the highest Security level. For example, if the danger level of a machine (or a part of it) is determined to be level 4, the safety level of the corresponding safety control circuit must also be level 4.

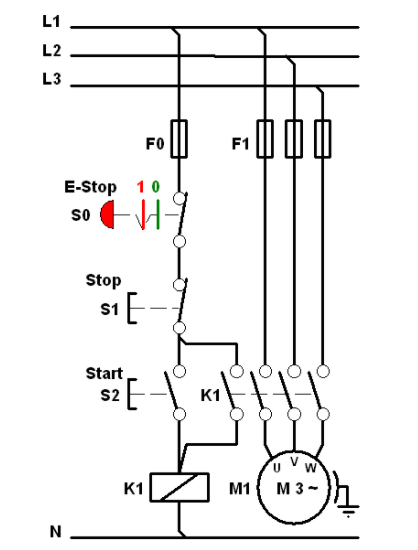

Class B requires that control circuits related to safety functions must be designed, selected and assembled with safety switching appliances that comply with basic safety guidelines and related standards. The safety control circuit must be able to withstand the operating intensity of the tone, and be able to withstand the influence of the working medium during the operation and the influence of the relevant external environment. Level B is the most basic level, and all other levels must meet the requirements of Level B. Compared with level B, level 1 requires the use of mature components, that is, components that have been widely and successfully used in similar applications, or are manufactured according to reliable safety standards, and use mature technology. A typical wiring example for class B and class 1 is shown in Figure 2:

In level B and level 1, the tolerance of the safety control system to faults is mainly achieved through the use of appropriate components. As shown in the figure, the fuse F0 and the emergency stop button S0 are connected in series in the main control loop. If a reasonable fuse and a reliable emergency stop button are used, the risk in this circuit is acceptable. But when any single fault occurs in the safety control circuit, such as the emergency stop button contact is welded dead, it will cause the loss of the safety function. Therefore, the safety level of this control loop can only be level B or level 1. In the design of dangerous machinery, Class B and Class 1 are rarely used. Usually the most commonly used are levels 2, 3, and 4.

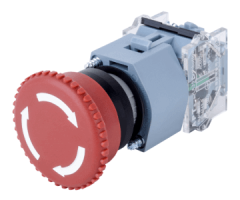

Extended learning: How does an emergency stop button work?

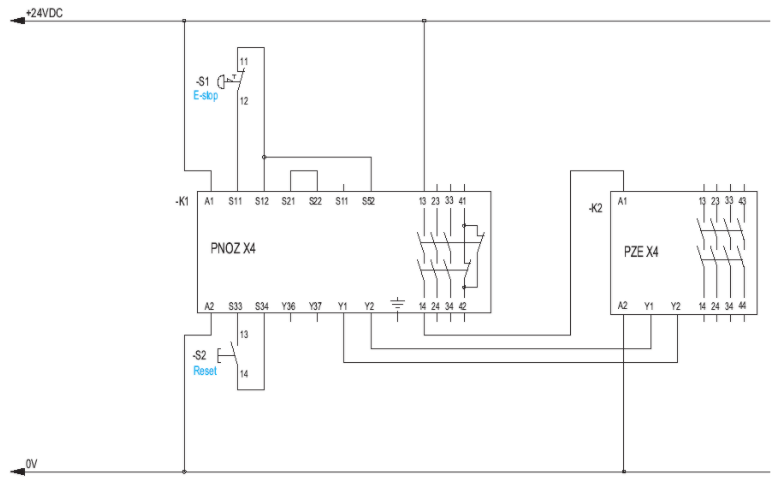

We can divide a simple control circuit into signal input part (such as emergency stop button, limit switch, grating), control part (such as relay, PLC) and output part (such as AC contactor for controlling motor). According to the description of the safety level in EN 954-1, to achieve safety level 2 and above, the control part must use safe components, such as safety relays, safety PLCs, etc. On the basis of the safety relay used to reach the required safety level, we can usually judge the level 2, 3, 4 through the wiring of the signal input part. We now take the emergency stop button as an example to analyze the application wiring of these three safety levels. If single-channel signal input is used to enter the safety relay, the safety level of this control circuit is at level 2, as shown in Figure 3.

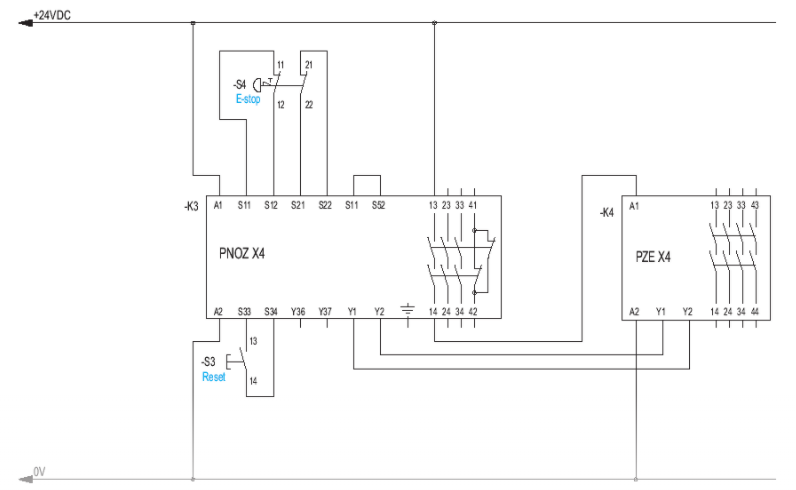

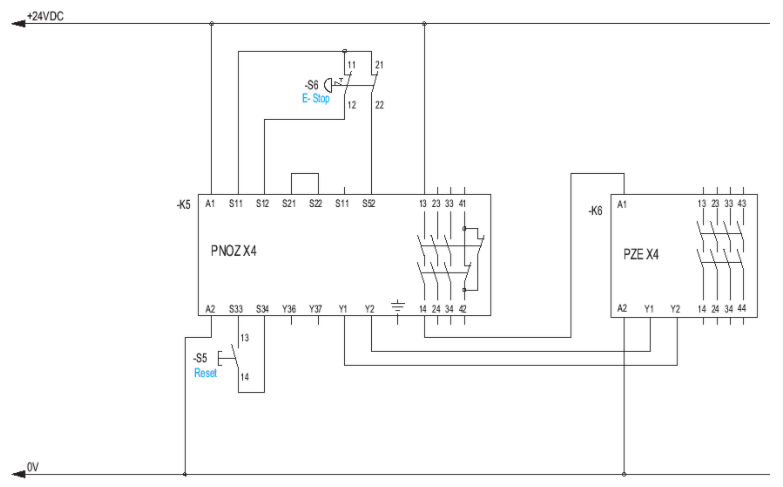

If dual-channel signal input is used, it enters the safety relay and cannot detect the short circuit between the two input contacts. Then the safety level of this control loop is at level 3, as shown in Figure 4.

If dual-channel signal input is used, it enters the safety relay and can detect the short circuit between the two input contacts at the same time. Then the safety level of this control loop is at level 4, as shown in Figure 5.