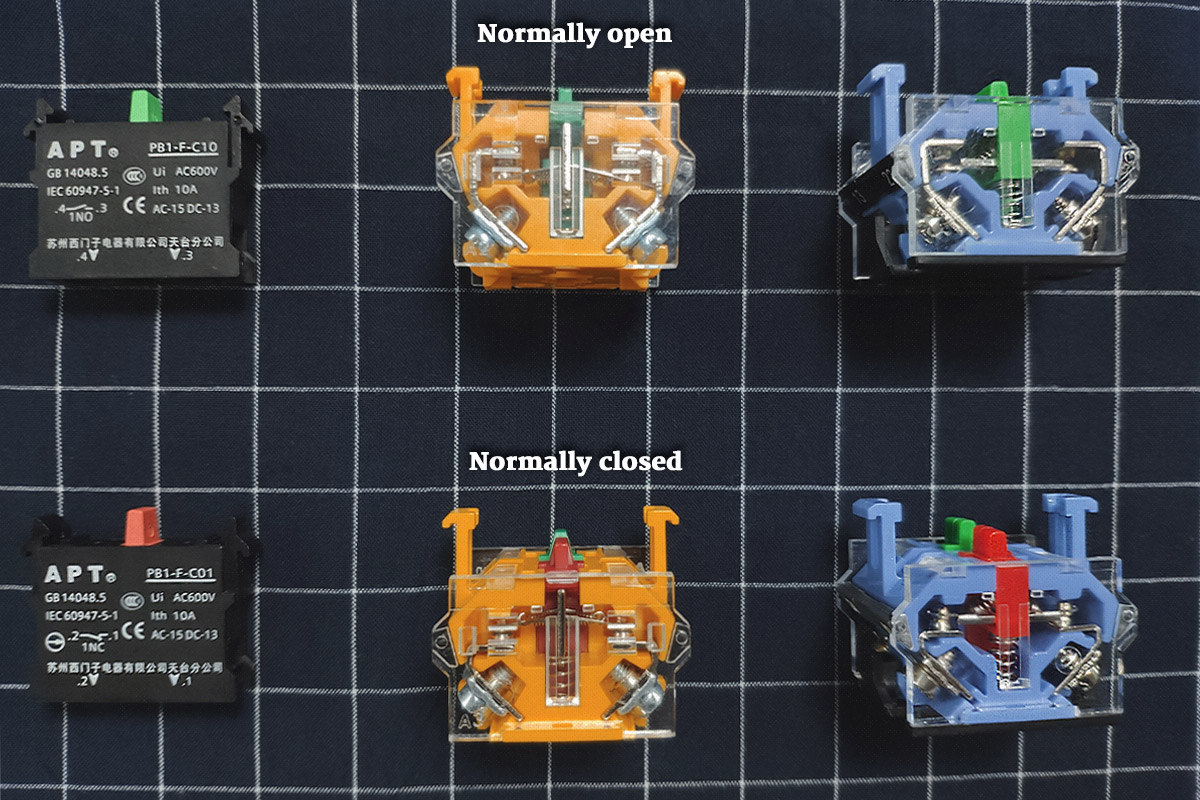

NO contacts and NC contacts

Anyone who has assembled an electrical control circuit or a control cabinet must be impressed by the indispensable "emergency stop" button. This kind of button used in emergency situations is mostly self-locking with red mushroom head, which is very eye-catching in the entire control system. Many electrical designers think that this button is only used to connect the normally closed contact to the control circuit of the electronic control system. After it is pressed, it is used to cut off the power of the entire control circuit, so that each coil in the circuit loses power and indirectly controls the main circuit to be cut off. Electric shutdown. When we design the control loop, why should we choose the emergency stop button with normally closed contact instead of the emergency stop button with normally open contact?

1. In terms of operating time, the time for normally closed contacts from closing to opening is much shorter than the time for normally open contacts from natural state to closing. Maybe you want to say, how can there be less? Such a short time does not matter. But I would like to say that this is especially important when an emergency stop is required in the event of danger. At this time, the shortest time, even milliseconds or even microseconds, is very important. You know, the accident happened in a very short time. You can think about it, in such a short period of time, you may not stop the machine or open the switch by using the normally open contact, and will causing major machine damage or personal injury. However, the use of normally closed contacts may stop the machine or make people get an electric shock for a shorter time, avoiding all this.

2. From the perspective of the button mechanism, we know that whether the emergency stop button is a normally closed or normally open contact, if it is not pressed in place (pressed to the end), it will bounce again, thereby making the action invalid. When using normally open contacts, when the emergency stop button is not pressed in place, the emergency stop has no effect (because the normally open contacts are not closed); when using normally closed contacts, it is different, regardless of emergency stop The button is not pressed in place, and only the contact is activated, and the emergency stop is effective.

3. In terms of its control circuit, it goes without saying that the most basic function of the emergency stop button is to stop in an emergency, avoiding mechanical accidents or personal accidents. However, due to the long-term operation of the machine, the line, especially the emergency stop line part, may cause a fault and open circuit. At this time, if the emergency stop button uses a normally open contact, the line fault of the emergency stop part will not be found. When the emergency stop button is used then it will be too late. When using normally closed contacts, when the emergency stop part of the line fails, the machine will stop at most, and the loss will be relatively small. It is based on the above reasons that when designing an electrical control system, it is best to use a normally closed contact for the emergency stop button.