Push button switch function

A push button switch is a control switch that uses a certain part of the human body (usually a finger or palm) to apply force and has a spring stored energy to reset. It is the most commonly used master electrical appliance. The allowable current through the contact of the push button switch is small, generally not more than 5A. Therefore, under normal circumstances, it does not directly control the on and off of the main circuit (high current circuit), but sends command signals in the control circuit (small current circuit) to control electrical appliances such as contactors and relays, and then they control the main circuit On-off, function conversion or electrical interlocking.

Siemens APT Push button switches

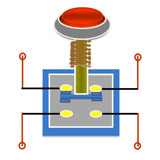

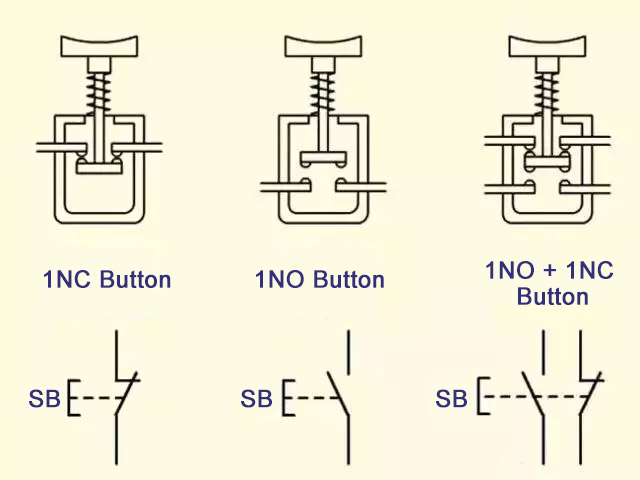

The structure principle and symbol of the push button switch

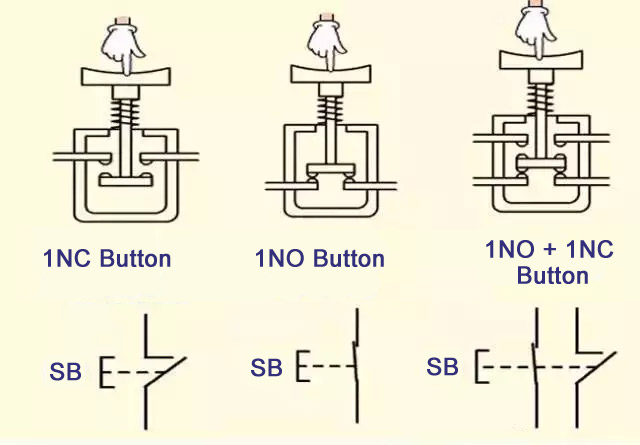

The push button switch generally consists of a button cap, a return spring, a bridge-type moving contact, a static contact, a pillar connecting rod and a shell.

The opening and closing state of the contact when the push button switch is not subjected to external force (ie, static), divided into stop push button switch, start push button switch and compound push button switch.

When the push button switch is subjected to external force, the opening and closing state of the contact changes:

Meaning of push button switch color

| Push button switch color | Meaning | Description | Application example |

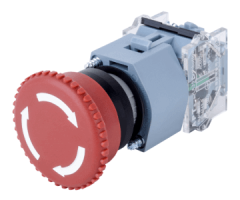

| Red | Urgent | Operation in danger or emergency | Emergency stop |

| Yellow | Abnormal | Operate in abnormal situations | Intervention to stop abnormal situations |

| Green | Normal | Start operation under normal conditions | |

| Blue | Mandatory | Operation when forced action is required | Reset function |

| White | No specific meaning | Start of general functions except emergency stop | Start/on (priority), stop/off |

| Gray | Start/on, stop/off | ||

| Black | Start/on, stop/off (priority) |

Push button switch structure code

K—open type, embedded in the operation panel;

H—protective type, with protective shell, which can prevent internal parts from being damaged by machinery or accidentally touching live parts;

Push button switch model and meaning

S—Waterproof type, with a sealed shell to prevent rainwater from intruding;

F—anti-corrosion type, can prevent corrosive gas from entering;

J—emergency type, with a big red mushroom push button switch (protruding out), used for emergency power off;

X-knob type, use the knob to rotate for operation, there are two positions of on and off;

Y-Key operation type, use the key to insert for operation, which can prevent misoperation or be operated by special personnel;

D—cursor push button switch, the push button switch is equipped with a signal lamp, which also serves as a signal indicator.

Selection of push button switchs

1. Select the type of push button switch according to the use occasion and specific purpose. For example, the push button switch embedded in the operation panel can be an open type; the cursor type that needs to display the working status; the key-operated type should be used for important occasions that need to prevent personnel from misoperation; and the anti-corrosion type should be used where there is corrosive gas.

2. Select the color of the push button switch according to the working status indication and working condition requirements. For example, the start button can be white, gray or black, and white or green is preferred. The emergency stop button should be red. The stop button can be black, gray or white, preferably black, or red.

3. Select the number of push button switches according to the needs of the control loop. Such as single push button switch, double push button switch and triple push button switch.

Common faults and treatment methods of push button switchs

| Fault phenomenon | Possible cause | Treatment method |

| Poor contact | The contact is burned out | Repair contacts or replace products |

| The surface of the contact is dusty | Clean the contact surface | |

| Contact spring failure | Rewind the spring or replace the product | |

| Short circuit between contacts | Plastic thermal deformation causes the terminal screws to touch and short circuit | Find out the cause of heat, troubleshoot and replace the product |

| Debris or oil forms a closed circuit between the contacts | Clean the inside of the button |

Recommended article:

How does an emergency stop button work?

What to pay attention to when using the emergency stop button?