Push Button Switch

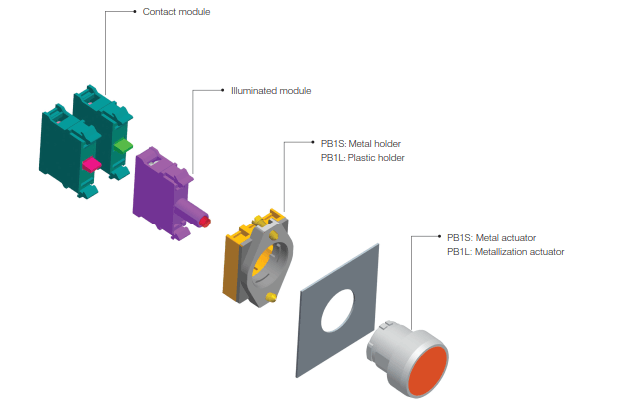

The push button switch is a device that turns on or off the power circuit by pressing the push part with fingers. The structure of the push button switch is divided into three parts: push unit, installation base and contacts module.If it’s an illuminated push button switch, it also includes light box components.

The push unit has a button part. When the operator presses the button part, it will move a certain distance towards the contact modules, which is often called the travel distance. And triggers the spring pieces or push rod of the contacts to open or close the contact between two contacts.

There is a protective front ring around the button part. The front ring is made of metal or plastic material. It is used to protect the button part and also plays a decorative role. If it is a push button switch with lamp, the button part will be made of transparent material, and the lamp will be placed in the hollow button part. The circuit of the lamp is independent with contacts load circuit. Common control voltage of the lamp is 6VDC, 12VDC, 24VDC, 110VAC, 220VAC.

The selection of push button switch needs to consider water-proof and dust-proof, that is, we often call IP level. There are IP40, IP54, IP55, IP65, higher can achieve IP66, IP67. The IP level is determined by the gap between the front ring and the button part, and the gap between the front ring and the mounting plate.

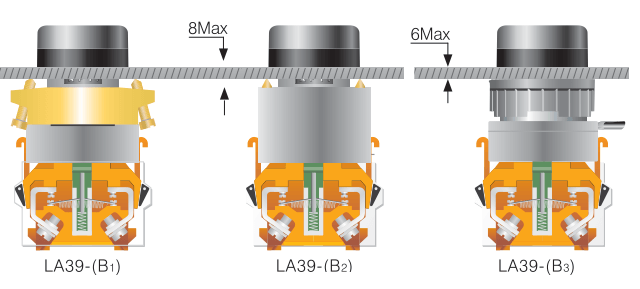

The mounting base is used to mount the push button switch to the mounting plate and connect the push unit and the contacts module. The installation and fixation of the push button switch requires a flat plate, which is called the installation plate by the engineer. It can be an independent plate or the shell of the installed equipment. The material of the plate includes metal, plastic or other materials. The surface of the board needs to be flat and the thickness is between 1-8mm.

Before installing the button switch, it is necessary to cut out a round hole on the mounting plate according to the size required by the installation of push button switch. Some push button switches need to be cut out a positioning slots to prevent them from turning when use. The common installation diameter of push button switch is 8mm, 10mm, 12mm, 16mm, 19mm, 22mm, 30mm, 35mm, 36mm, But the cut out hole usually is 0.3mm larger than the diameter of push button switch to facilitate installation.

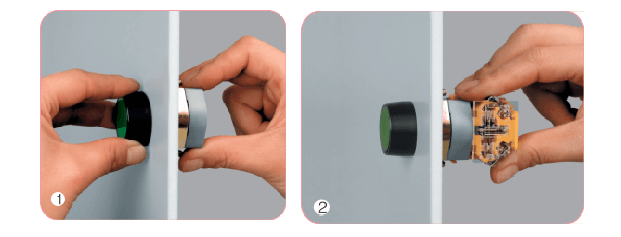

There are three types mounting base according to the different fixation methods: two auxiliary screws fix, nuts fix and clips fix. Different application fields, engineers choose the appropriate installation mode when selecting models. The materials of mounting base: metal and plastic. The type with two auxiliary screws who oblique direction installation is most firmly.

Two auxiliary screws are fixed obliquely, which has the advantage of firm installation and not easy to loosen. Shortcoming is installation trouble, time-consuming. The advantages of nut rotation fixation are convenient and fast, and the shortcoming is that it is easy to loosen on the vibrating equipment. Buckle fixation is a new way of installation, in recent years. It is easy to install and firm. However, due to make and manufacturing process, there are only plastic base at present, which is not suitable for equipment with serious oil pollution or high temperature.

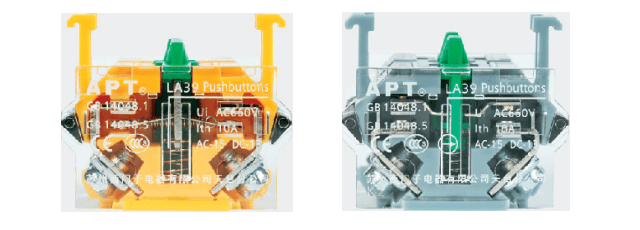

The contacts module is the most important part of the push button switch, which is composed of the contact, the plastic shell of protecting the contact, the spring pieces or the push rod driving the contact action. The contacts modules have 1NO, 1NC, 1NO and 1NC, 2NO and 2NC, 3NO and 3NC, 1NO and 2NC, 2NO and 1NC, 1NO and 3NC, 3 NO and 1NC, which can achieve 6 pairs of contacts at most. Contact materials are copper, silver, gold, or silver nickel alloy, silver nickel alloy surface plating gold.

The surface of contacts has flat, sphere and inverted triangle. flat contact area between the upper and bottom contacts is larger, but the surface is easy to form oxide layer after a long time. The inverted triangle contacts can pierce the oxide layer through the prick to maintain good conductivity, when push the button, but the production technology is more complex. So, spherical contacts are used widely.

The electrical performance of push button switch is mainly determined by contacts material and contacts surface processing technology. For more notes on push button switch, there is a more detailed in FAQs.

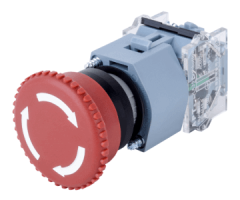

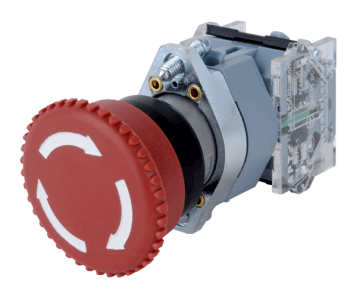

Emergency Stop Switch

When the equipment is in a dangerous state, in order to ensure the safety of people life and equipment, people need a electrical switch that can cut off the power supply quickly and reliably, and make the equipment stop work, which is the emergency stop switch. The emergency stop switch is similar to the push button switch, except that its touch part is replaced by a mushroom shaped actuator with a larger diameter, such as, 60mm, and the color of mushroom actuator is red. The surface of mushroom actuator is printed with an obvious arrow or “emergency stop” character. According to the classification of safety control circuit in EU, the emergency stop switch can reach level 3-4. You can also learn more through the FAQs of the emergency stop switch.

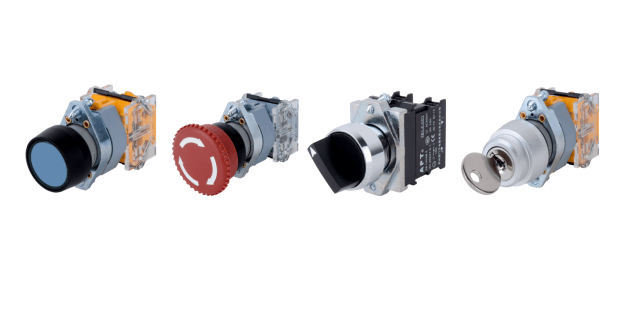

Selector Switch

When it is necessary to control the multi position state circuit, the push button switch can’t meet the needs, and the selector switch is needed to control the circuit. The selector switch is a kind of switch apparatus which can be used for two or more circuit power supplies or load change-over. The selector switch is composed of three parts: operation part, mounting base and contacts module. The mounting base and contacts module are the same as push button switch, which is not described here. The following describes the operating components of the selector switch.

The selector switch can be divided into two positions and three positions selector switches according to the number of rotating gears, which can be return type or action hold type. The push button switch is to press the button part by fingers to open or close the contact. The selector switch drives the contact to open or close by turning the handle. The selector switch can be selected with lamp or without lamp, and the light of selector switch with lamp can be seen from the transparent handle.

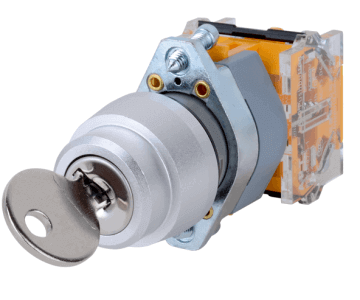

Key Switch

The key switch is also a kind of selector switch, only the operating handle of the selector switch is replaced with a key. The key switch requires the operator to have a matching key in his hand to operate the equipment, and strengthens the authority management of the operation action. Key switch, a key can operate multiple key switches, or a key can only operate a specified key switch.